Bend software entrepreneur tackles robotics

Published 12:00 am Sunday, March 6, 2016

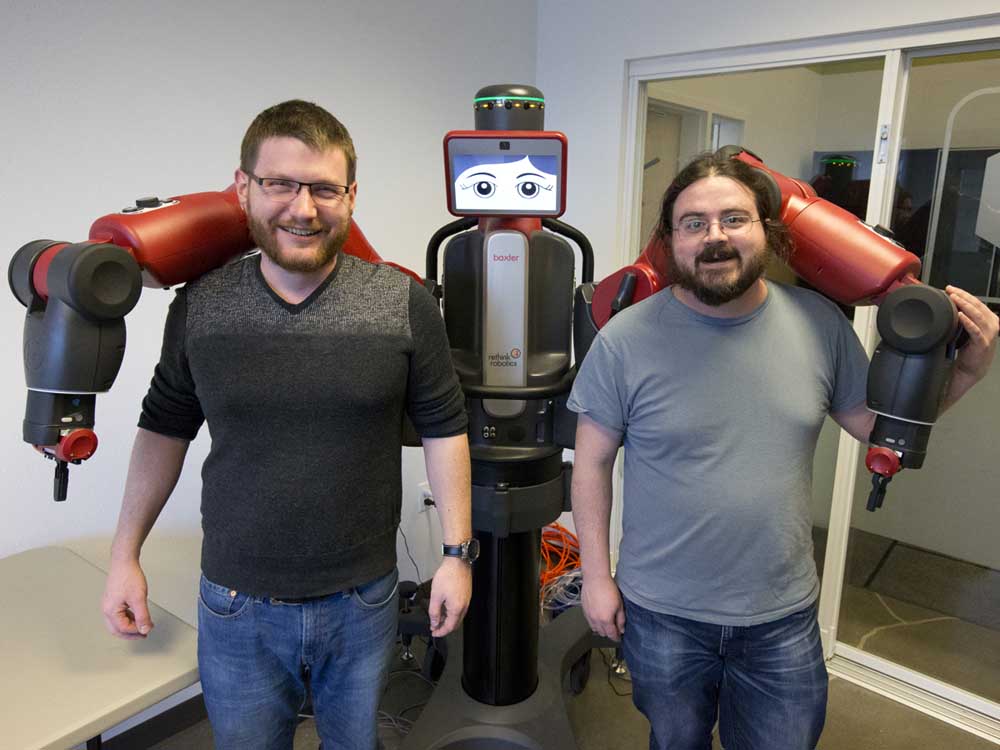

- Photos by Andy Tullis / The BulletinMark Silliman (left) and Austin Meyers, who are partners in Bold Robotics, stand with their robot, named Abbe, in the 1001 Tech Center in Bend. Silliman purchased the robot in 2015 and hopes to have it assist manufacturing firms in Oregon before the end of 2016.

Mark Silliman has advice for visitors looking for the office of his new software business, tucked in a corner of the co-working space within the 1001 Tech Center:

“Look for the robot.”

Trending

Abbe, a 6-foot-tall red humanoid robot built by the Boston-based firm Rethink Robotics, is hard to miss in the approximately 250-square-foot office. While it is mostly placid now, Abbe and robots like it could be using software written by Silliman and the team at Bold Robotics LLC to help manufacturing firms in Oregon before the end of 2016.

“This is a technological revolution, more than just being another Snapchat or whatever,” he said.

Silliman, who has founded six companies, considers himself a serial entrepreneur. One of those companies, Smartwaiver, which provided a way for companies to digitize liability waivers, was founded in Bend in 2012. By the summer of 2015, the company had passed 7 million waivers signed.

But Silliman had other passions. He has been interested in robotics since college, and how robots and people can interact in particular. He purchased Abbe early in 2015 with an eye toward teaching the robot to do household chores.

By the summer of 2015, Silliman said, hardware improvements had helped transform robots from the dangerous, one-purpose units that began appearing on factory floors in the 1970s into more affordable and precise units that can complete a wide variety of tasks with the right software.

“When it became clear that this robotics business was possible, I began negotiating the sale (of Smartwaiver),” he said.

Trending

Silliman stepped down as the CEO of Smartwaiver in December, following an undisclosed investment. Bold Robotics was formally founded in October, according to information from the Oregon Business Registry, but Silliman said the company has only been truly active since January.

Bold Robotics’ vision is to allow companies — primarily in the manufacturing sector — to download shared, cloud-based software that can allow robots to execute a variety of different tasks. Silliman said most robots come with basic software to allow them to complete rudimentary tasks, but more complicated software has historically been prohibitively expensive.

Instead, Bold Robotics is using a software-as-a-service model, where centrally hosted software can be rented through a subscription, which Silliman said will cut down on costs for smaller manufacturers.

“What’s exciting about this now is you can purchase this arm, and you can trust it to do task A for three months and task B for three months, and it will take you less than a day to switch tasks,” Silliman said.

After another Bend-based company, the optical sensor manufacturer PulsedLight Inc., was acquired in January, Silliman brought over PulsedLight employee Austin Meyers to help write code and design the software.

“I’m a sucker for startups,” Meyers said. “It was really fun to come over here and start dealing more with machine learning and cameras.”

Automation is not new for manufacturing companies, in Oregon or elsewhere. Central Oregon firms like Outback Manufacturing, a Bend-based company that designs a variety of different specialty metal and plastic parts for everything from knee replacements to air filters, use machines to help with cost and precision.

Sam Shawe, co-owner of Outback Manufacturing, said the company has around a dozen computer-controlled machines to help with manufacturing. Because the company relies so heavily on precision, having machines that can manufacture a part correctly each time is a boon, Shawe said.

“Every time you touch a part, you can load it incorrectly,” Shawe said.

However, smaller manufacturers don’t always have the luxury of spending money on machines that are suited to one specific task. Silliman described a robotic arm — like those used in factories with joints that allow them to pivot — as a tool that can accomplish an almost unlimited mix of tasks with the right software. Brian Vierra, venture catalyst for Economic Development for Central Oregon, said even companies like Amazon are looking for new robotic innovations. EDCO invited Silliman to speak about Smartwaiver and Bold Robotics during February’s PubTalk.

“What I think (Silliman) is talking about is really the next step,” Vierra said.

Bold Robotics’ software would allow robots and robotic arms to switch between a variety of manufacturing tasks, including tending to other machines and maintaining quality control, without requiring any coding knowledge from workers in the factory. While the tasks will be fairly basic at the outset, Silliman said individual robots can learn similar skills from one another through the main software hub, a process known as machine learning.

“It is making the entire system smarter, which benefits all the small businesses,” he said. “That’s a distinct competitive advantage that we can bring to the table that could not be done with just one custom software.”

Because Bold Robotics is targeting early adopters, Silliman said, the company plans to purchase robots from a mix of manufacturers from North America and Europe, upload Bold Robotics software and lend them to interested companies for 30 days. If the companies like what they see after the trial period, they could hang onto the robots and utilize the software on a subscription basis.

While robotics represents a growing market opportunity for companies in a variety of industries, one of the challenges is getting the general public comfortable with interacting with machines. Scot Brees, president of the High Desert Makers and a robotics enthusiast, said a lot of people still base their perception of robots on movies like “Terminator,” which can be an impediment to getting them comfortable with the idea of having robots be part of daily life.

“Science fiction movies still exploit that fear,” Brees said. “I think we??re a few years away from seeing that change.”

He added that the change is likely to come from the younger generation. Brees said robotics programs for middle-school and high-school students in Central Oregon have come a long way in recent years, and are beginning to bridge some of those gaps in understanding.

“We aren’t the ones who grew up with the technology,” Brees said of his generation.

For Bold Robotics, Silliman has focused on reaching out to manufacturing companies around Oregon to gauge interest in the company’s software. He said it is reasonable to see robotic arms using Bold Robotics software in manufacturing companies by the second quarter of 2016.

“I don’t think a lot of people understand how quickly this can happen,” Silliman said. “I can tell you that the limitation is purely software. So frankly, it’s how quickly Austin and I can write code.”

— Reporter: 541-617-7818, shamway@bendbulletin.com