Oregon’s biodiesel rule to change

Published 4:00 am Friday, February 25, 2011

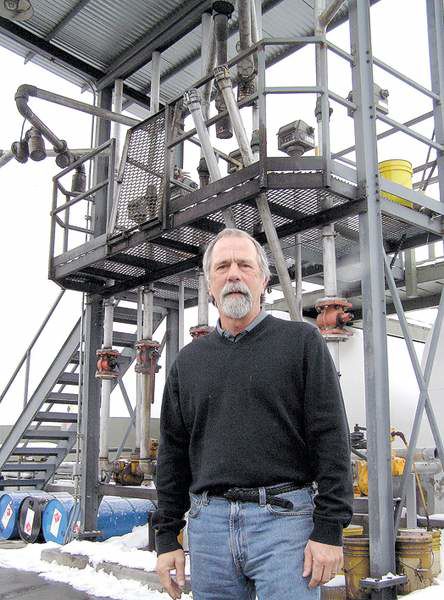

- Larry Kimmel, vice president of Bend Petroleum, is concerned about the potential for fuel gelling problems when regulations that raise the amount of biodiesel that must be mixed with petroleum-based diesel from 2 percent to 5 percent take effect April 1.

The amount of biodiesel, made from oil seed plants and animal fats, required to be blended with petroleum-based diesel in Oregon will increase from 2 percent to 5 percent April 1.

The higher percentage of biodiesel required by the Oregon Legislature comes despite complaints from fuel distributors, truckers, farmers and others about biofuel blends exacerbating diesel gelling problems in Central and Eastern Oregon during cold weather.

Oregon’s renewable fuel standard passed by the Legislature in 2007 required diesel sold in Oregon to contain 2 percent biodiesel beginning in 2009, with an increase to 5 percent once the in-state production of biodiesel hit 15 million gallons, which occurred last year, according to a statement released Wednesday by the Oregon Department of Agriculture.

Clark Cooney, deputy administrator of ODA’s Measurement Standards Division and manager of the Motor Fuel Quality Program, said he has heard complaints from fuel distributors, truckers, farmers and others who oppose the new state mandate for petroleum diesel to contain 5 percent biodiesel, as well as the 10 percent ethanol blended gasoline requirement.

Cooney said biodiesel and ethanol are both biofuels, but they are very different products made from different types of ingredients.

“Biodiesel is made from fatty acid methyl esters derived from soy bean oil, cannula oil, safflower oil, used cooking oil, animal fats and those types of things,” Cooney said.

Ethanol, on the other hand, is a form of alcohol, similar to moonshine, currently made mostly from distilled corn and other grain crops, which has raised some concerns that growing those crops for ethanol displaces production of food crops and animal feed, which in turn drives up food prices.

However, Cooney said concerns about ethanol propelling food prices sky high could turn out to be a moot point with advances in new technology. That includes a new plant being built in Umatilla County with the potential to replace corn/grain-based ethanol with cellulosic ethanol made from agricultural and forest wastes such as corn and wheat stalks, grass straw and leafy and woody material from forest thinning projects or poplar and cottonwood tree plantations.

“There are people really for biofuels and people really against biofuels,” Cooney said. “There are various arguments on both sides.”

But whether people like it or not, the Legislature has mandated use of the 5 percent biodiesel mix known as B5, and the 10 percent ethanol/gasoline mix known as E10.

Cooney said both biodiesel and ethanol have solvent qualities that clean gunk out of fuel systems. That initially caused some fuel system clogging problems when biofuel mandates first took effect in 2007 and 2009. But once the initial rush of fuel line gunk was cleaned out and people changed their fuel filters, he said complaints about those problems faded away.

Gelling concerns

The ODA acknowledged in Wednesday’s report that the agency “received some complaints about winter fuel gelling from consumers in Central and Eastern Oregon after the state’s 2 percent biodiesel blending requirement for diesel fuel began in 2009.”

Larry Kimmel, vice president of Bend Petroleum, which distributes gas and diesel to 22 Shell stations across Central and Eastern Oregon, in the Columbia Gorge and parts of the Willamette Valley south of Portland, said he saw and heard about numerous problems with clogged fuel filters and diesel gelling when Oregon imposed its 2 percent biodiesel blend.

“Two years ago, when we had a cold snap with several days of sub-zero temperatures, we had gelled fuel everywhere,” Kimmel said.

To help reduce the risk of winter gelling that Kimmel and other fuel dealers, truckers and others feared could increase with the B5 requirement in cold regions, the Legislature passed a law in 2010 allowing fuel dealers to add anti-gel chemicals to prevent gelling during winter.

Kimmel said it costs fuel distributors about 3 cents per gallon of blended diesel to add anti-gel chemicals.

Since distributors started adding anti-gel additives, Kimmel said there haven’t been nearly as many complaints from truckers and other customers about blended diesel gelling in their fuel systems. But he said the weather hasn’t been cold enough this winter to gauge whether the additives will do the job next time temperatures drop below zero and stay there for several days.

Kimmel said he is concerned that boosting the biodiesel from 2 percent to 5 percent may lead to even greater gelling problems the next time winter temperatures drop below zero for several days in a row.

“We use chemical additives to prevent gelling from Nov. 1 through March 1. As mild as the winter has been this year, we probably could have gotten by without it, but you can’t take a chance and wind up with a bunch of truckers getting gelled up,” Kimmel said.

“I do think we may have some difficulties effectively treating gelling after we go from 2 percent biodiesel to 5 percent,” Kimmel said.

New blends

Cooney said when the ODA investigated complaints in 2009 about diesel gelling, the agency found the most common problem stemmed from truck stops and gas stations having to blend the biodiesel with diesel themselves, resulting in some inconsistent blends. Today, the blending is done by distributors using standardized equipment and methods, before the fuel is shipped to station operators.

The Oregon Petroleum Association has worked to educate its members on the potential causes of fuel gelling and best practices to prevent gelling in biodiesel blended fuel, according to the ODA.

“If a consumer does experience fuel gelling problems this coming winter, or any other fuel quality concerns for that matter, we’d like to hear from them,” Cooney said.

As for the new B5 biodiesel requirements, Cooney said the city of Portland has required B5 since 2006, and trucking companies and fuel stations rarely report problems.

The new statewide 5 percent biodiesel blend, as well as the state’s 10 percent ethanol requirement for gasoline, are designed to help clean the air and support Oregon agricultural production of oil seed crops used to make biodiesel; and certain types of corn, grains or plant cellulose used to make ethanol, according to the ODA.

“Biodiesel is a cleaner fuel than conventional diesel and reduces many types of harmful emissions,” according to the ODA.

“I’m all for the environment and decreasing dependence on foreign oil,” Kimmel said.

In the wake of demonstrations and rioting in the Middle East the past few weeks, Kimmel said his cost for diesel rose 13.4 cents at 6 p.m. Wednesday, and the wholesale price he pays for gasoline jumped 5 cents per gallon on Monday, 3 cents on Tuesday and another 7 cents on Wednesday, for a total of 15 cents over three days this week.

That translates to a cost to his dealers of $3.34 per gallon of gas, and he said dealers generally need to charge customers at least 11 to 12 cents more to cover employee and overhead costs.