Bend company making medevac flights safer

Published 4:51 am Wednesday, December 20, 2017

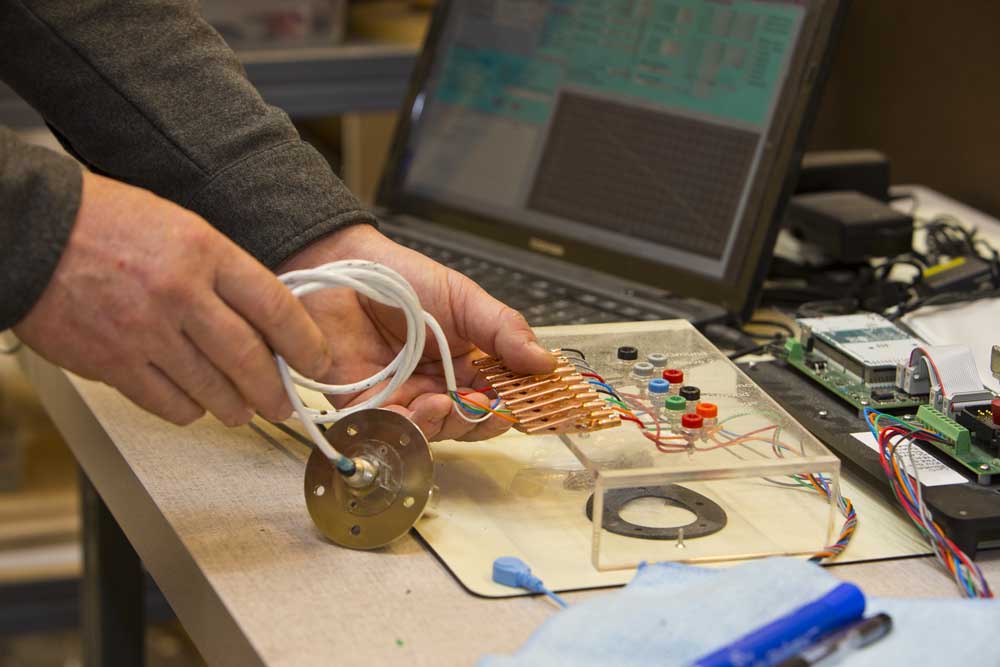

- CEO Scott Philiben of CiES Inc. on Tuesday programs a sensor used in a fuel probe designed at the lab in Bend. (Andy Tullis/Bulletin photo)

A Bend company is contributing to a solution for a deadly problem that plagues helicopters used as air ambulances.

CiES Inc., maker of a device that accurately measures the amount of fuel in aviation fuel tanks, created a version compatible with a fuel bladder designed to prevent a post-crash explosion. The company recently shipped 100 units, with 40 more orders soon on their way out the door, said CiES CEO Scott Philiben on Tuesday.

The CiES fuel probe is part of a crash-resistant fuel tank developed by Robertson Fuel Systems, of Tempe, Arizona, with Vector Aerospace, a global company that specializes in aircraft maintenance. The Federal Aviation Administration on Dec. 4 certified the Roberston-Vector fuel tank for retrofitting two models of Airbus helicopters, the AS350 and the EC130 B4. Airbus helicopters are commonly used for medical evacuations.

The CiES contribution to the improved fuel system isn’t the unit’s ability to survive a crash, said Bill York, director of engineering at Robertson. The CiES fuel probe is accurate and economical, all significant improvements over existing technology, York said.

The CiES probe “is giving a higher fidelity signal than what you would get out of the old, resistance-style system, in a reliable fashion at an economical price,” York said. Philiben said the basic model is built to outlast the useful life of most aircraft.

He said the fuel probes, designed in Bend, are made at a machine shop in Bend and their circuit cards are programmed in Portland.

The floats that ride on thin aluminum arms of the probe are made in Italy at a factory that once made ski goggles.

The Robertson-Vector crash-resistant fuel system addressed a well-documented need, said York and Philiben.

Between March 2011 and October 2015, 22 people worldwide died in 10 crashes of AS350 helicopters, according to reports Philiben provided. All of those incidents, plus two nonfatal crashes, involved post-crash fires. One of those incidents, the crash of a medical helicopter owned and operated by Air Methods Corp., a St. Louis-based air ambulance company, brought public attention to the problem in the U.S, York said.

In July 2015, an Air Methods AS350 medevac helicopter crashed and burned shortly after takeoff in Frisco, Colorado. One onboard nurse suffered a back injury, and a second nurse and the pilot were seriously burned; the pilot eventually died. Had the helicopter, which fell about 100 feet into a parking lot, been fitted with a crash-resistant fuel system, the pilot may have lived and the nurse spared burn injuries, Philiben said.

“What was amazing was the people survived that crash,” he said, “they just didn’t survive the fire.”

The National Transportation Safety Board, after an investigation, noted the absence of a crash-resistant fuel system and later issued a safety recommendation.

York said Air Methods is committed to retrofitting several hundred helicopters in its fleet with the Robertson-Vector fuel system.

The FAA does not yet require owners of Airbus helicopters to install crash-resistant fuel systems, although the NTSB in March 2016 recommended the FAA and the European Aviation Safety Agency require their installation. The FAA responded that it had started the regulatory process to require the retrofit.

Only helicopter designs approved by the FAA after 1994 are currently required to have those systems, York said. The Airbus design, which dates to the 1970s, is grandfathered.

— Reporter: 541-617-7815, jditzler@bendbulletin.com