Mt. Bachelor and Prineville plan for future with biomass facilities

Published 5:45 am Monday, August 7, 2023

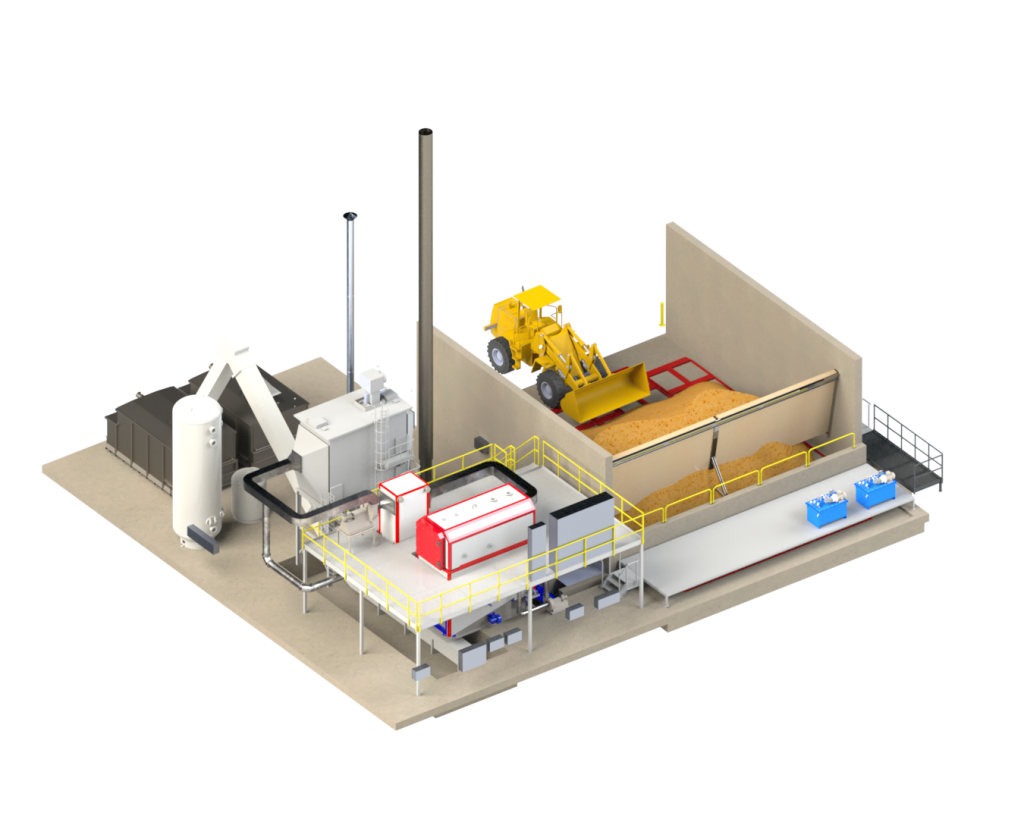

- An artist's rendering shows Mt. Bachelor's proposed biomass facility that could provide nearly all the ski area's indoor heating needs.

As a way to help manage forests surrounding Central Oregon, Mt. Bachelor ski area and the city of Prineville are planning construction of biomass facilities that burn unwanted forest material to create heat and electricity.

Mt. Bachelor plans to build a 1.2-megawatt facility to heat its buildings in the winter and avoid having to use 225,000 gallons of propane each year. The ski area, owned by Powdr Corp., is on track to complete its project in 2024. It has had financial help from the U.S. Department of Agriculture, Deschutes County and the Oregon Department of Energy.

Just 57 miles away, Prineville plans to build a 24.9-megawatt power plant to generate electricity by burning debris and unwanted thirsty juniper trees cleared from the Ochoco National Forest. That project is in the permitting stage.

Both projects dovetail with the state’s renewable energy standards, said Amy Schlusser, Oregon Department of Energy senior energy policy analyst. One goal, the Renewable Energy Portfolio Standards, aims for 50% of the electricity purchased in the state to be produced from qualifying renewable energy sources by 2040.

“Biomass is one of the qualifying resources under the Renwable Energy Portfolio Standards,” Schlusser said. “It has been deemed by the Legislature as preferable to other sources of non-renewable electricity.”

Turning brown into green energy

Oregon ranks 19th among states in terms of biomass generating capacity, according to a 2020 report on the state of renewable energy in Oregon. The majority of the biomass facilities use direct-fired combustion of biomass to generate electricity in Oregon. The combustion creates heat and steam and drives turbines to create energy. And most of them are affiliated with pulp and paper mills or lumber yards, according to the report.

Using forest material in a biomass facility, like what’s being proposed in Prineville, not only reduces wildfire risks, but also saves the U.S. Forest Service from having to haul away or collect the material for burning later. The Forest Service would earn a small income from selling the material, said Kevin Keown, Forest Service natural resources and planning staff officer at the Ochoco National Forest & Crooked River National Grassland.

“The Prineville Renewable Energy Project is a fit with the city’s mission of improving quality of life in Prineville through the multitude of benefits the project will provide, including reducing wildfire risk and improving air quality, increasing water quality and quantity, and creating living wage jobs,” said Steve Forrester, Prineville city manager. “It’s a proactive solution to address forest and wildfire issues while generating renewable, baseload power for our region.”

The U.S. Forest Service Wood Products Infrastructure Assistance Program supported Prineville’s efforts with a $1 million grant in April that is being used to fund permit and design work. The grant is intended to improve, establish or retrofit facilities that purchase and process byproducts from ecosystem restoration projects on federal or tribal land, according to the Forest Service’s grant website.

Prineville pitches biomass to save the forests

The Prineville facility will take two years to complete at an undetermined cost and is in the permitting phase. The city hopes to have permits in hand by year’s end and move onto construction, said Caroline Ervin, city of Prineville capital projects manager.

And it anticipates it can sell the electricity it generates from the forest debris to a power company.

“There are a host of benefits, from helping the forest, wildfire improvements and removal of juniper trees and saving water,” Ervin said. “The idea is this can be replicated in other areas, so not just a one-off project, but have it in other forested areas.”

The city has a site selected, but would not disclose, the location.

The 850,000 acres of the Ochoco National Forest can provide a lot of material, like small trees removed to improve the health of the forest and reduce risk of wildfire, Keown said. The city also plans to tap into recycled lumber and other plant materials that can be used in a biomass facility. Having a facility close to the forested land reduces hauling costs too.

“Most of our projects we pile up materials, limbs and tree tops, or we haul the material to a land site,” Keown said. “Occasionally, we’ll sell the material for fire wood. In general, the profit margins are lean on material like this.”

When removed, juniper trees, which can suck up more than 30 gallons of water a day, can affect water flows in the region, according to scientists.

Crook County declares drought emergency for fourth straight year

Biomass as a heater

Other biomass facilities use woody material to create heat, like what is being proposed by Mt. Bachelor. European ski resorts have been using biomass. While combustion of biomass does emit some carbon and isn’t a emissions-free clean energy source, as compared to other renewable energy sources like wind and solar, it is cleaner than burning fossil fuels, Schlusser said.

State commits funding for biomass facility at Mt. Bachelor

Mt. Bachelor plans to tap into the 47,000 acres of Forest Service land surrounding the ski area and the attempts to clear it of wildfire debris. Much of it can be burned in a biomass facility.

“There are differing opinions on if we should use it as a renewable energy feedstock, but reducing wildfire risk by removing wood debris on natural land can be challenging and expensive,” Schlusser said. “Economic incentives are needed for this to be an economically viable biomass feed stock.”

The ski area uses 225,000 gallons of propane to heat its buildings. The biomass facility would create enough heat that Mt. Bachelor anticipates it would only require a fraction of propane for heat.

The ski area would not discuss the cost of the facility, but has raised $3.5 million from government support. Using woody material sourced directly from the forest restoration and management activities, the biomass boiler can burn without screening or drying the material, according to a Mt. Bachelor corporate statement.

Initial estimates call for the system using about 1,000 tons of wood chips a year and would offset 93% of the propane use, said Tanner Fields, Mt. Bachelor sustainability specialist.

“We want to do as much as possible to reduce the build up of forest fuels,” Fields said. “We anticipate we’d have years of fuel supply based on the current acreage at the Deschutes National Forest.

“We have always wanted to help manage the wildfire risk. Our mission is to reduce the emissions and be environmentally sustainable.”