Gas permit would change emissions

Published 5:00 am Wednesday, June 1, 2011

- Gas permit would change emissions

At a complex of buildings surrounded by trees, just off Highway 97 south of Sunriver, huge engines are hard at work, pushing billions of cubic feet of natural gas toward California.

The compressor station is one of many along Gas Transmission Northwest’s pipeline from British Columbia to California. They are spaced about every 60 miles, said company spokesman David Dodson. The compressor station to the north is in Madras, and the next to the south is in Chemult.

Trending

The Bend station’s Title V air quality permit is up for renewal by the Oregon Department of Environmental Quality. The new permit would increase the amount of carbon monoxide the facility is allowed to release, while decreasing the amount of nitrogen oxides.

The changes in the permit are due to more refined measuring information for the turbines, said Walt West, environmental engineer with DEQ. The new emission limits are still lower than federal standards.

“Even with these new emission factors, they have not exceeded those thresholds,” he said, noting that if the thresholds were reached, it would trigger an evaluation of the facility and possibly new control measures.

The emissions come from the station’s compressor turbines, which burn some of the natural gas that runs along the pipelines. If the three turbines at the Sunriver compressor station ran all day, every day for a year, they would burn through more than a million cubic feet of natural gas, West said, enough to supply 5,000 average-sized homes for a day. But the turbines don’t typically operate that much.

Still, the plant’s emissions are significant enough to require a Title V permit, which is also used for facilities like the Brightwood plant in Madras.

“They do combust quite a bit of natural gas, which requires them to have the Title V permit; it’s a very large permit,” West said.

Trending

The compressor station, which is operated remotely, serves two parallel pipes. One, 36 inches in diameter, was installed in 1961, and a second, 42 inches in diameter, was commissioned in 1994, Dodson said. The pipeline can receive as much as 2.9 billion cubic feet of natural gas a day at the British Columbia border. With the average home consuming about 200 cubic feet of natural gas a day, according to the American Gas Association, that’s enough to supply about 14.5 million homes. And the pipes can deliver 2.2 billion cubic feet of natural gas at Malin at the California border.

The amount of natural gas varies day by day, and last week the pipeline was carrying less than capacity, with about 1.2 billion cubic feet arriving at Malin. The Gas Transmission Northwest pipeline is one of only two interstate pipelines running through Oregon. Branches of the Williams/Northwest Pipeline run down the Willamette Valley from Washington and also from Umatilla County across the northeast corner of the state to Idaho.

The compressor stations move the gas down the Gas Transmission Northwest pipeline from north to south.

“What you have at a compressor station is a jet engine,” Dodson said. “It’s the same kind of engine that’s on a jet airplane.”

There are three engines in the Bend compressor station — a 19,200-horsepower General Electric LM 1600, a 14,300-horsepower Cooper Rolls Royce Avon, and a 19,500-horsepower Solar/Titan unit.

“There’s some significant energy involved,” Dodson said.

The first compressor was installed in 1968 and replaced several times. The second was installed in 1970, and the third was installed in 2001 and started operating in 2002, according to the DEQ permit.

The jet engines turn a big fan inside an enclosure. That big fan turns a second fan, which is attached to the pipeline. The second fan compresses the gas, pushing it through the pipeline at about 15 to 25 mph.

The maximum allowable operating pressure for the station, as set by the federal government, is 910 pounds per square inch. If the pressure gets higher than that, Dodson said, the engine turns off.

Without the compressor stations, the gas might move, he said, but it might not move in the direction you want it to go. And when the volumes were low, the gas would be pulled along only by people at the end of the pipe using their stoves and heaters.

“There’d be a pull, but it might not flow to California,” Dodson said.

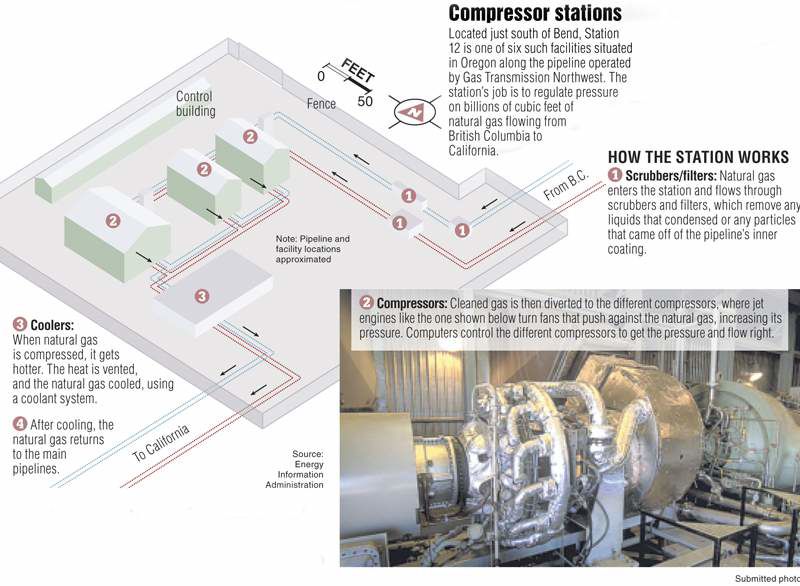

Compressor stations

Located just south of Bend, Station 12 is one of six such facilities situated in Oregon along the pipeline operated by Gas Transmission Northwest. The station’s job is to regulate pressure on billions of cubic feet of natural gas flowing from British Columbia to California.

How the station works

1. Scrubbers/filters: Natural gas enters the station and flows through scrubbers and filters, which remove any liquids that condensed or any particles that came off of the pipeline’s inner coating.

2. Compressors: Cleaned gas is then diverted to the different compressors, where jet engines like the one shown below turn fans that push against the natural gas, increasing its pressure. Computers control the different compressors to get the pressure and flow right.

3. Coolers: When natural gas is compressed, it gets hotter. The heat is vented, and the natural gas cooled, using a coolant system.

4. After cooling, the natural gas returns to the main pipelines.

Source: Energy Information Administration